- Description

-

Rovtech Solutions Ltd.’s background is in the design and manufacture of ROVs (remote operated vehicle) and submersible lights and cameras for marine and oil & gas applications. In 2009 we were approached by Sellafield Ltd to adapt a standard ROV for use in their spent fuel storage ponds. The decommissioning of a number of very large storage ponds containing a variety of fuel wastes and contaminated machinery and equipment and sludge residue is a priority on the nuclear site. A solution was required to manipulate the contents of the ponds and consolidate many tons of spent fuel.

- Content

-

Challenge

The environment in the storage ponds is radioactive, which has a detrimental effect on certain materials and electronic components. The water is caustic, ph11 which is corrosive to certain plastics and metals. Visibility is affected by the build-up of algae, and the disturbance of sludge from the pond floor which has built up over several decades. The sludge contains fuel fragments.

Solution

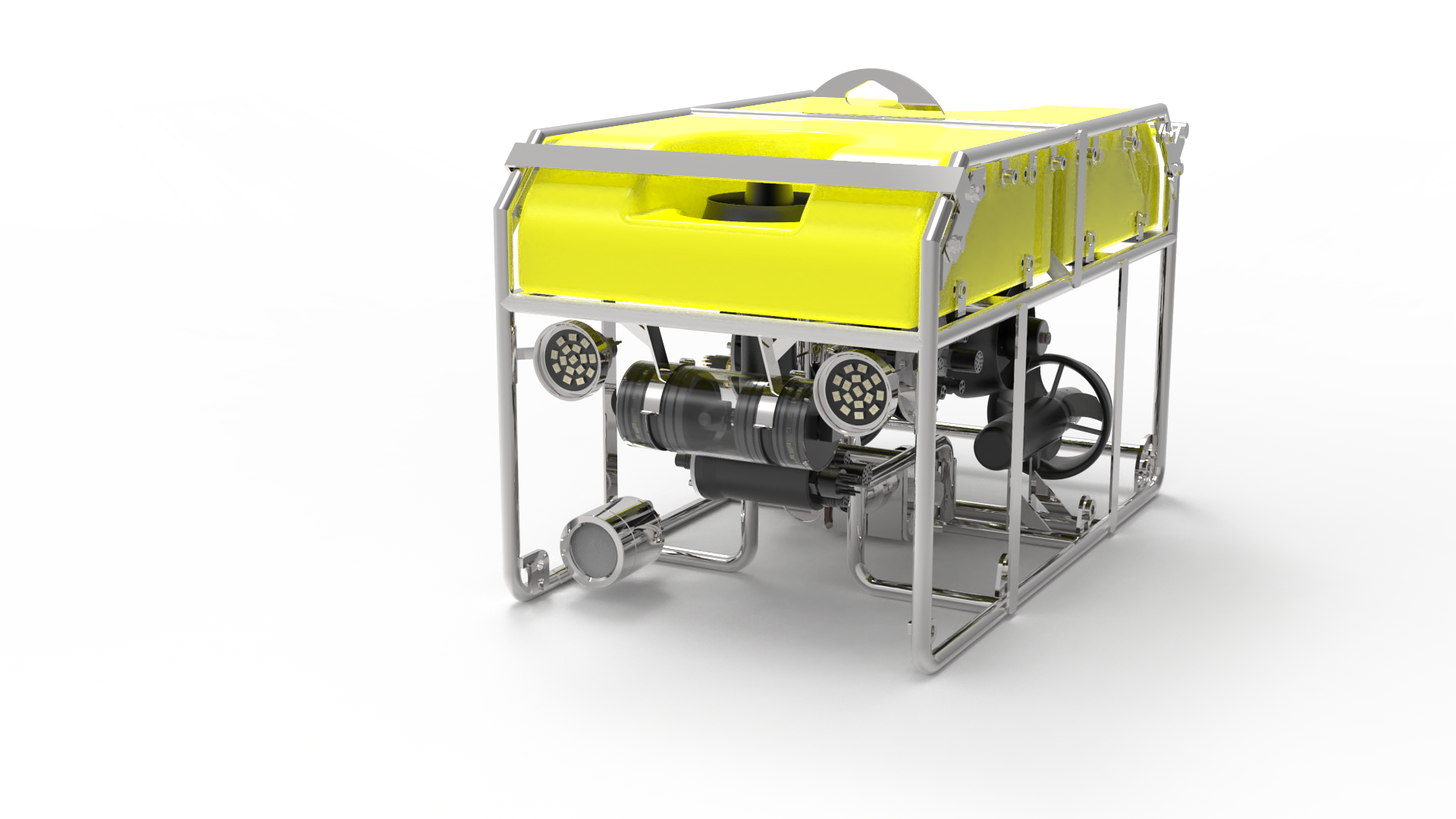

The solution was to adapt a standard Rovtech ROV design which, at the time, was a popular marine and oil & gas work class vehicle. The use of electronic circuits and processors, which are most susceptible to the affects of radiation, needed to be kept to a minimum, or relocated out of the pond. Stainless steel cameras and lights were used to mitigate the corrosive effects of the water and provide a level of radiation shielding. The vehicle frame was fabricated from Stainless steel to mitigate the corrosive effects of the water. The thruster motors used were simple DC motors with the motor control removed from the vehicle (out of the radioactive water) and kept on the surface. Other standard materials were replaced with more radiation tolerant alternatives.

The design of the Seaker ROV was adapted to remove areas where radioactive sediment could collect, and space was made between components to allow for the cleaning of the vehicle with high pressure hoses.

Standard practice in the nuclear industry resulted in the removal of all sharp edges and corners to avoid puncturing operators PPE (personal protective equipment) during maintenance.

Result

Initially, the requirement was to provide a means to move a small amount of pond inventory and to provide a view of the pond contents while traditional, manual manipulation was used. It was immediately recognised that the capability of the vehicle was much broader than anticipated, use case could be expanded and that the lifespan of the vehicle justified the cost. After six years of use the Seaker vehicles are recognised as having broken the ground for multiple operations in the nuclear ponds. Five vehicles have been used, with all, including the original machine still in use.

The Seaker ROV can now be equipped with manipulators, grippers, hydraulic cutters, sludge pumping equipment, suction, sonar and many other end effectors.

https://www.bbc.co.uk/news/business-33849026 https://www.youtube.com/watch?v=4cvlxr-mM3A&feature=youtu.be

Conclusion

The use of ROVs in the nuclear industry is now commonplace, with many more modern machines coming into the industry. This strategy brings risk and numerous, more modern, machines have succumbed to the effects of radiation. Rovtech’s Seaker ROV remains the only high radiation tolerant vehicle available and continues, in various guises to deliver results.

Innovative ROV Solutions for Nuclear Decommissioning Challenges

Rovtechs Adaptation of the Seaker ROV for Sellafields Radioactive Storage Ponds

Innovative ROV Solutions for Nuclear Decommissioning Challenges

Rovtech Solutions Ltd. adapted their Seaker ROV to address Sellafield Ltd's challenges in radioactive spent fuel storage ponds. Despite harsh conditions, the Seaker's innovative design and radiation-tolerant materials have set it apart, making it an industry standard in nuclear decommissioning operations for over six years.